Round Bottle Labeler HA-TB01

Round Bottle Labeler HA-TB01

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Workflow

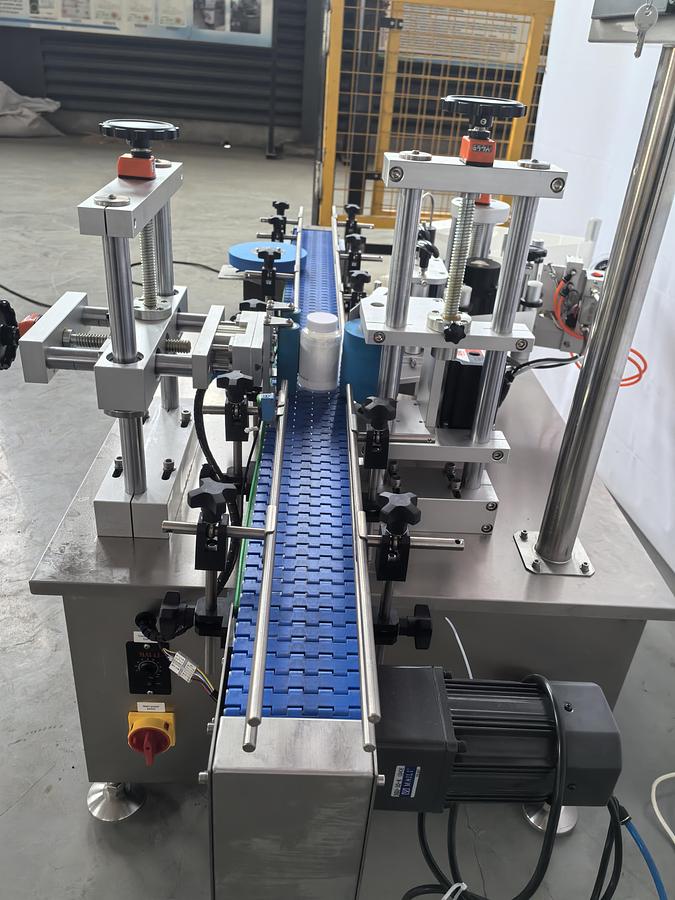

- The labeling machine is designed for efficient and precise label application. Products are placed onto the infeed conveyor and automatically guided into the bottle separation area. An alignment mechanism ensures accurate bottle positioning before the pressing unit smoothly transfers them into the labeling zone.

- A photoelectric sensor detects each incoming bottle and sends a signal to the PLC . The PLC processes the signal and activates the servo motor to dispense the label. The label is then firmly applied to the bottle by a rolling mechanism. After labeling, products continue along the conveyor to the next stage of the packaging line or are collected in a designated container.

- This automated process ensures high-speed, accurate, and consistent labeling for a wide variety of bottle shapes and sizes.

Product Advantages:

- Wide Compatibility

- Suitable for a variety of round containers.Optional circumferential positioning detection allows labels to be applied at precise locations on the bottle surface.

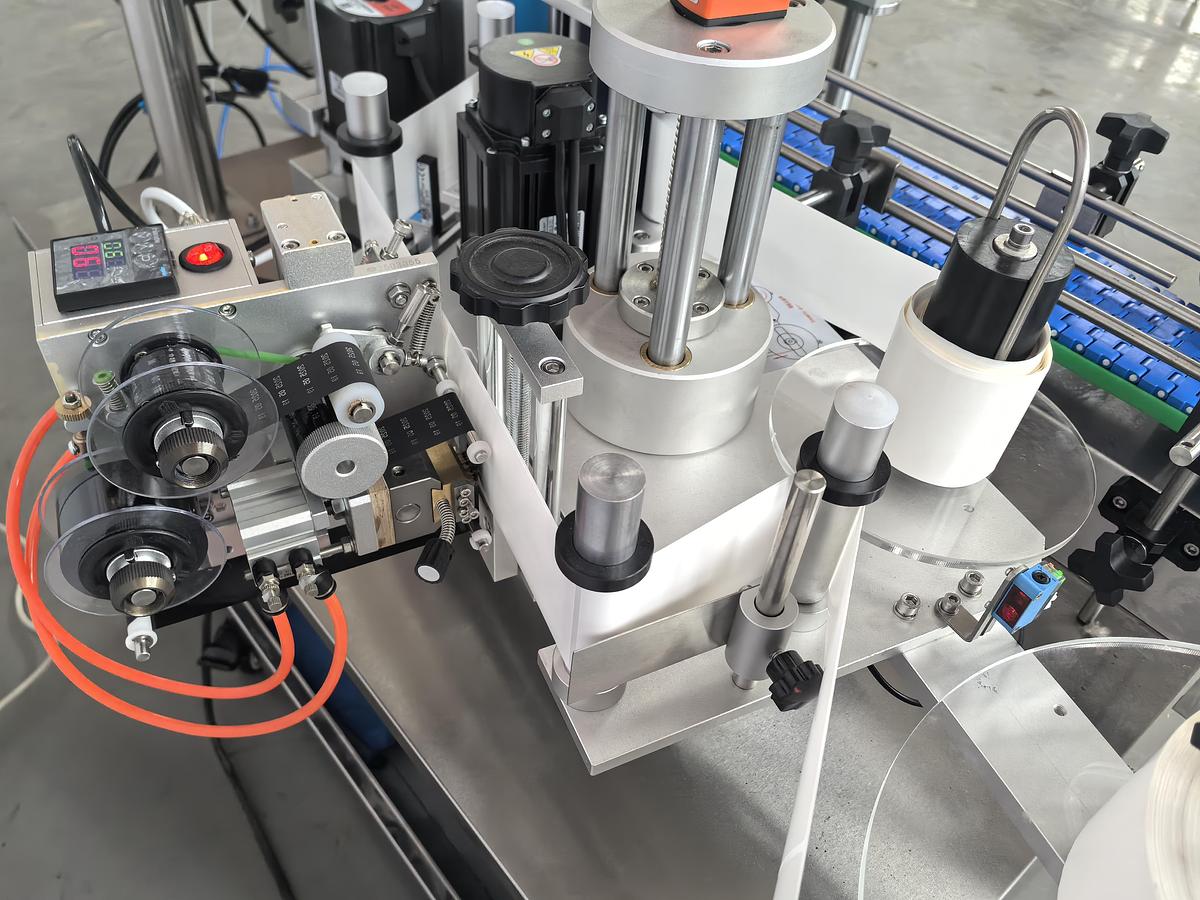

- High-Precision Labeling System

- Tension-Controlled Label Feeding ensures stable label output with consistent label length and positioning.

- Pre-Feed Label Mechanism offers excellent label flatness and high positional accuracy.

- Adaptive Roller Pressure adjusts labeling force based on different bottle shapes and materials, improving label adherence.

- Robust Drive & Control System

- Equipped with a premium imported labeling system.

- Powered by PLC and servo motor modules, delivering exceptional stability and synchronization during label dispensing.

- Intelligent & Fully Automated Operation

- Labels are automatically dispensed when the photoelectric sensor detects a passing bottle.

- Seamlessly integrates with upstream and downstream equipment, eliminating the need for dedicated operators and reducing labor costs.

- Intuitive User Interface

- Features a Chinese or bilingual (Chinese-English) control panel for easy operation and quick setup.

- Superior Mechanical Design

- Durable Label Rolling Mechanism: Uses high-wear-resistant rubber for long service life.

- Precision Bottle Separation System: Achieves accuracy up to ±5mm. Easily adjustable for bottles of different sizes—no extra change parts required.

- Heavy-Duty Frame: Modular and standardized design with full interchangeability for continuous 24/7 operation.

- Hygienic & Corrosion-Resistant Construction: Made with SUS304 stainless steel and T6 aluminum alloy, fully GMP-compliant and rustproof.

Specifications

| Manufacturer | Hongda |

| Model | HA-TB01 |

| Year | 2024 |

| Condition | New |

| Stock Number | 1 |

| Compatible Bottles | Diameter ≤3.94", Height 1.57"–7.09" |

| Label Size | Max width 4.3", length based on bottle circumference. |

| Production Capacity | 30–90 bottles/minute |

| Power Supply | 110Vac 50/60Hz 0.6KW |

| Air Supply | 87 - 116 psi |

| Machine Dimensions | 69"×37"×55" (L×W×H) |

| Weight | 485 lbs |

| Paper Roll Specifications | Inner diameter:3.0” External diameter:13.8” (Max) |