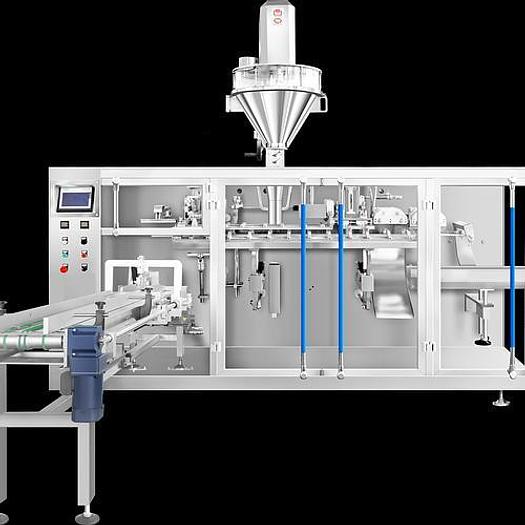

Horizontal Pre-made Bag packaging Machine with Powder Filling Feeder HA-210NG&HA-LX

Horizontal Pre-made Bag packaging Machine with Powder Filling Feeder HA-210NG&HA-LX

Contact us for price

Location:Ontario, CA

or

Call +1(626)3202070

Description

Horizontal Pre-made Bag Packaging Machine

1.Overview

- The horizontal pre-made bag packaging machine is widely applicable across various industries, including food, personal care and home care products, and pharmaceuticals. It supports a wide range of laminated packaging materials, such as paper-plastic, plastic-plastic, aluminum-plastic, and PE composites.

- Using pre-made pouches ensures low material waste, precise sealing, and aesthetically pleasing packages—enhancing product appearance and overall market competitiveness.

- With high versatility, the machine can be configured with different dosing systems according to the material characteristics. It is suitable for the automatic packaging of granules, powders, solid blocks, liquids, semi-preserved foods, toys, hardware parts, and more.

2.Application

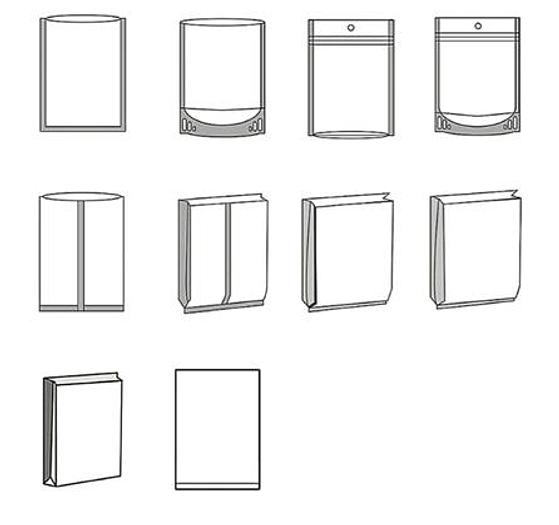

- It supports a variety of pouch types including three-side seal, four-side seal, stand-up pouches, stand-up zipper bags, and custom-shaped bags, with flexible bag-picking methods such as top pick-up, bottom pick-up, and paging type.

- The machine is suitable for filling capacities up to 33.8 fl oz and allows for easy switching between different bag sizes.

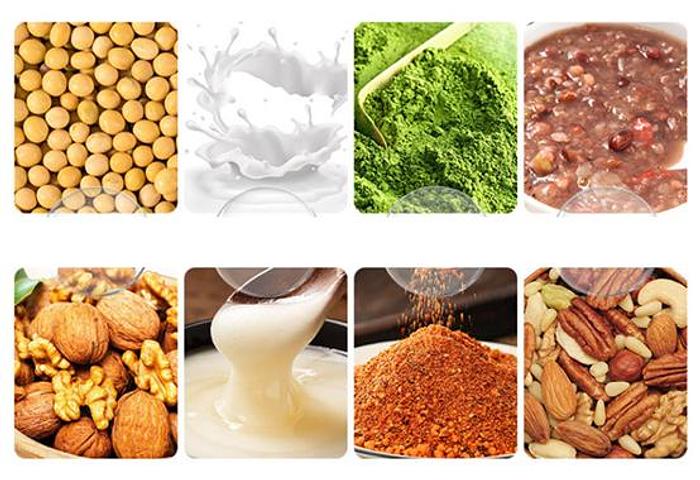

- It is capable of packaging various materials, including

- liquids:detergents, wine, soy sauce, vinegar, juice, ketchup, and jams

- block products:like peanuts, dried fruits, chips, nuts, candies, and pet food

- granules:seasonings, additives, crystalline seeds, sugar, and agricultural products

- powders:flour, milk powder, glucose, pesticides, and fertilizers

3.Equipment Advantages

- Easy Operation: PLC control with a touch screen interface for simple operation.

- Variable Speed Control: Adjustable packaging speed within a specified range.

- Automatic Detection: Prevents material addition and sealing if the bag is not fully opened, reducing material waste.

- Safety Features: Door safety stop and alarms for abnormal air pressure or heating tube failure.

- Efficient Bagging: Paging system for high bag separation and loading efficiency.

- Low Maintenance: Imported engineering plastic bearings require no lubrication, reducing contamination.

- Quiet Operation: Vacuum generator for bag picking and separation, minimizing noise.

- Premium Packaging: Uses pre-made bags with perfect designs and high-quality seals for better product appearance.

- Food Safety Compliance: Made with food-grade 304 stainless steel to meet hygiene standards.

- Versatile Packaging: Can handle liquids, pastes, granules, powders, and irregular shapes with different measuring devices.

- Wide Bag Compatibility: Works with various materials like multi-layer composites, aluminum foil, PE, PP, and paper bags.

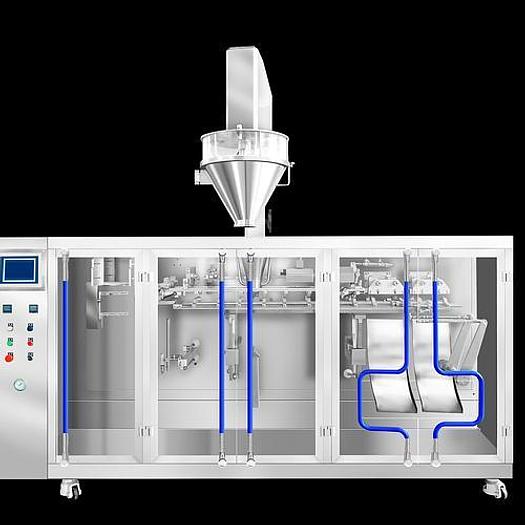

4.Transmission Structure

- The machine uses chain drive to operate three sets of internal cams and three sets of dividers, enabling various functions.

- The transmission structure is designed with modular components, simplifying the equipment structure, improving stability, and enhancing efficiency. Maintenance and repairs are quick and easy.

- All transmission components are located at the back of the machine to avoid contact with materials, preventing corrosion.

- The electrical cabinet is independently located on the side of the machine, unaffected by product characteristics.

- The control system uses renowned brands such as Siemens (Germany) and Mitsubishi (Japan), with electrical components from Schneider (France), temperature controllers from Omron (Japan), and servo motors and drivers from Panasonic (Japan).

Powder Filling Feeder

1.Overview

- The screw-type powder filling feeder is a specialized packaging equipment designed to accurately measure and fill powdered products into containers such as bottles, bags, or cans.

- It utilizes a rotating screw mechanism for precise dosing and is suitable for industries such as food, pharmaceuticals, chemicals, and cosmetics.

2.Core Features

- Screw Filling System

- Uses a screw feeder (screw auger) for measurement and filling.

- Adjustable screw speed and pitch enable both volumetric and weight-based accurate filling.

- High Precision Filling

- Suitable for powders with either good or poor flowability.

- Some models are equipped with weighing sensors, with an accuracy range of ±0.5% to ±1%.

- Wide Applicability

- Can handle a variety of powders, such as spices, flour, milk powder, protein powder, and pharmaceuticals.

- The hopper and screw size are adjustable, allowing compatibility with different container types.

- Waste Reduction

- Anti-drip design prevents powder spillage.

- Some models include vibration or agitation devices to prevent powder caking.

- Automation Options

- Semi-automatic (manual feeding) or fully automatic (integrated with a production line, including conveyors and sealers).

- PLC control with a touch-screen interface for easy operation.

- Compliance & Safety

- Made of food-grade stainless steel (SS304/SS316), meeting GMP, FDA, or CE standards.

3.Applications

- Food Industry: Milk powder, coffee powder, seasonings, flour, sugar, etc.

- Pharmaceutical Industry: Pharmaceutical powders, health supplements, active pharmaceutical ingredients (APIs).

- Chemical Industry: Laundry powder, pigments, additives.

- Cosmetic Industry: Talcum powder, loose powder, powdered cosmetics.

Specifications

| Manufacturer | Hongda |

| Model | HA-210&HA-LX |

| Year | 2024 |

| Condition | New |

| Stock Number | 1 |

| Bag size | Bag mouth width: 4.72–8.27 in, Bag length: 5.12–12.6 in |

| Packing speed | ≤40 bags/minute(It depends on the fluidity and specific gravity of the material and other characteristics) |

| Filling machine | Screw-type Powder Filling Machine |

| Hopper Capacity | 6.6USG/13USG (25L/50L) |

| Weighing Range | 0.35–1.76 oz/1.76–3.53 oz/3.53–17.64 oz(10-50 g/50-100 g/100-500 g) |

| Dosing Accuracy | ±0.035-0.176 oz(±1-5 g) |

| Power Supply | 110Vac, 1-Phase/200-230Vac, 2-phase, 50/60Hz,5.5KW |

| Air source parameter | 87-102psi/396GPM(0.6-0.7Mpa/1.5m³/min) |