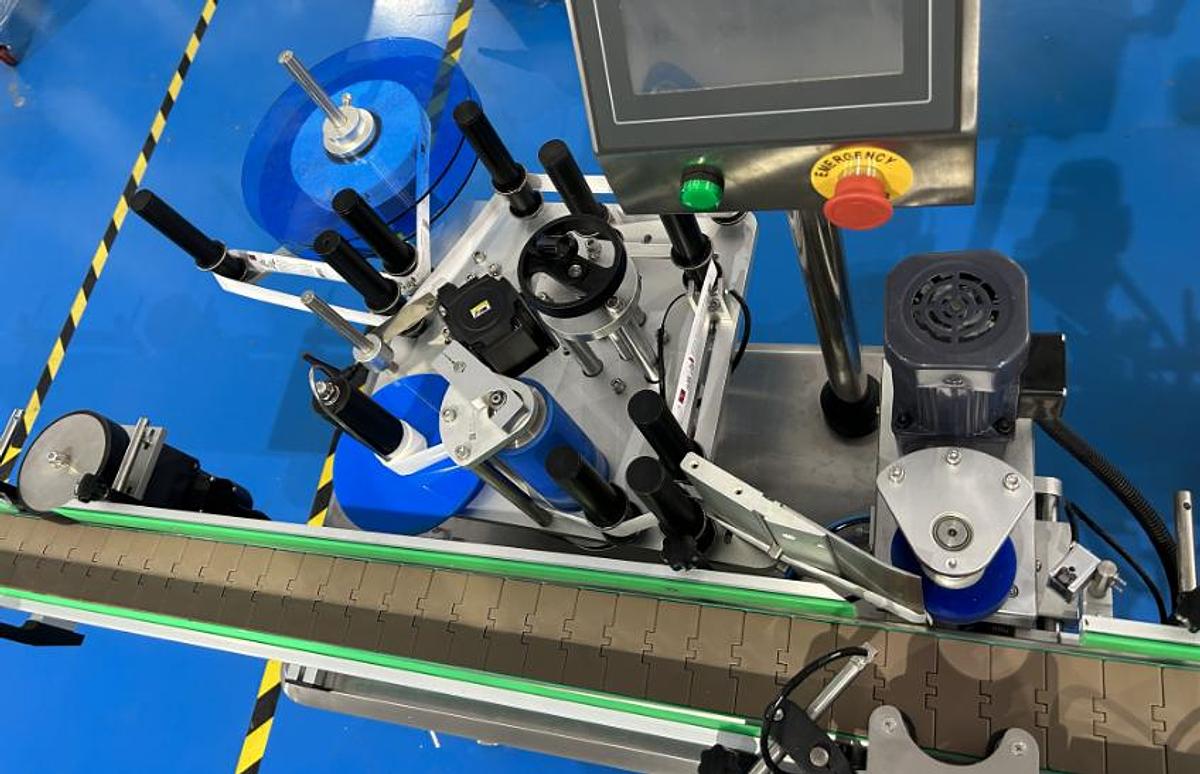

Positioning Labeling Machine

Positioning Labeling Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Working Principle:

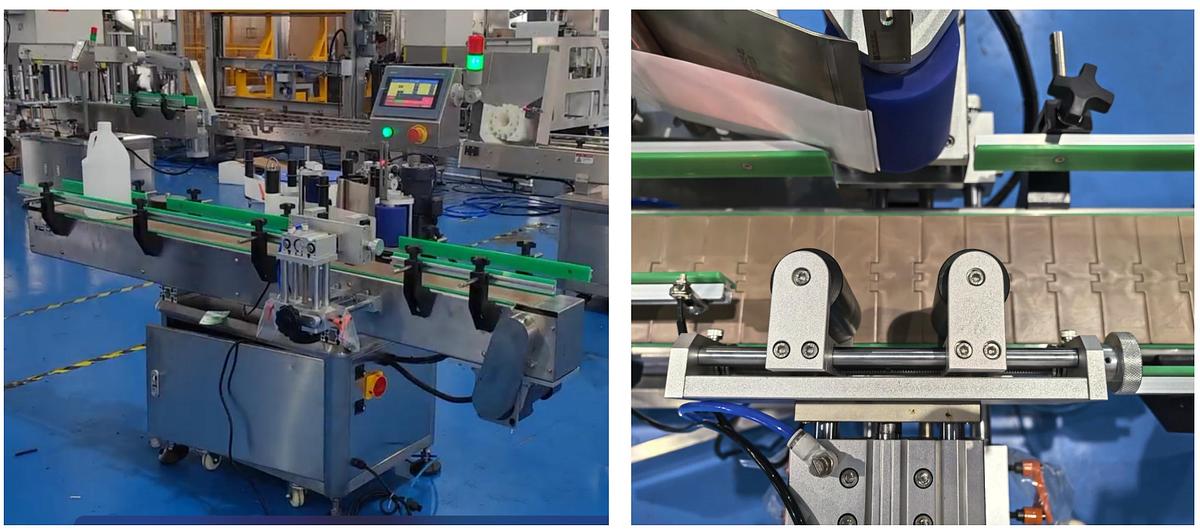

- Packaging items are placed on the labeling machine conveyor and transported to the bottle separation area. Bottles are aligned and guided by the holding mechanism into the labeling zone. A photoelectric sensor detects each bottle and sends a signal to the PLC, which controls the servo motor to dispense labels. Labels are applied using a rolling mechanism. After labeling, bottles are conveyed to the next process.

Key Features

- Adjustable Production Speed: Production speed can be set freely and automatically adjusts to match any production line for optimal efficiency.

- Automatic Fault Detection: The machine stops and issues an alert in case of abnormalities such as label run-out, ribbon break, ribbon depletion, counter settings reached, or mechanical faults.

- High-Performance Servo Motor: Delivers highly stable and synchronized label dispensing with a response speed up to 300 cycles/min and strong torque.

- Durable Label Rolling Mechanism: Uses special rubber material for the rolling mechanism, ensuring high wear resistance and long-lasting performance.

- Precise Bottle Separation: Differential bottle separation mechanism with accuracy up to ±5 mm. No need to change parts when switching bottle sizes, saving costs and simplifying adjustments.

- Robust & Modular Construction: Machine base and components are standardized and modular for full interchangeability. Designed for 24/7 operation, ensuring safety and stability.

Specifications

| Manufacturer | Hongda |

| Model | DW-TBJ |

| Condition | New |

| Stock Number | 20 |

| Product Height Range | 1.6"–11.8" (40–300 mm) |

| Label Height Range | 0.8"–4.7" (20–120 mm) |

| Label Length Range | 0.6"–13.8" (15–350 mm) |

| Labeling Speed | 30 bottles/min (adjustable) |

| Labeling Accuracy | ±0.04 inch |

| Power Supply | 200-240Vac,50/60Hz,0.55Kw |

| Machine Weight | 485 lb |

| Air Pressure | 87–116 PSI (0.6–0.8 MPa) |