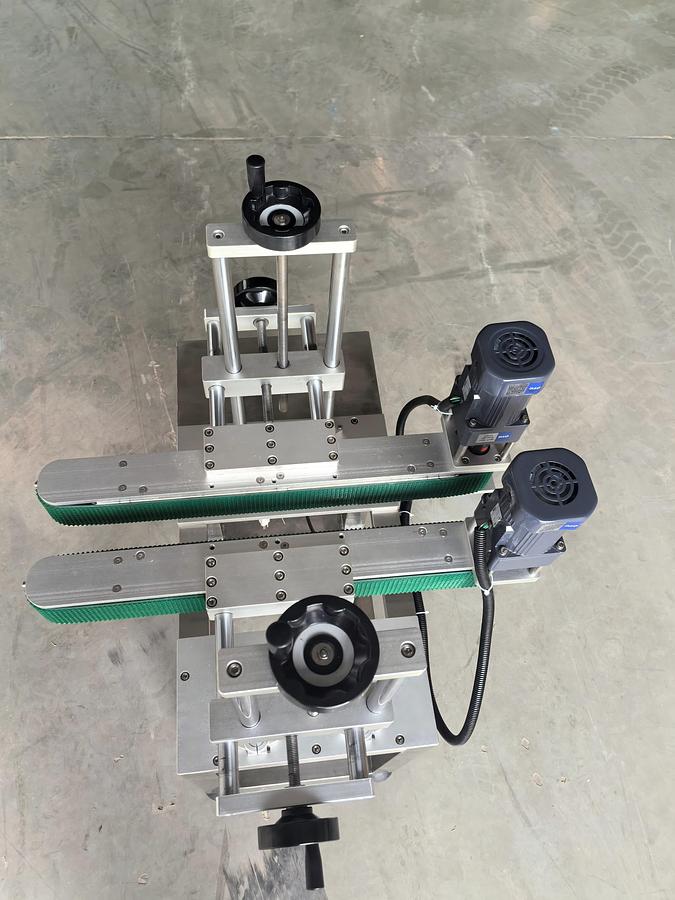

Bottle Clamping Machine

Bottle Clamping Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

- The belt-type bottle gripper is an automated handling system that combines synchronized conveyor belts with precision clamping mechanisms. It is designed for high-speed production lines, ensuring accurate bottle positioning, stable transfer, and smooth integration with downstream processes.

- Its primary advantage is the balance it achieves between high-speed operational stability and flexible conveying. This makes the system well suited for hygienic, high-efficiency applications in the beverage, food, pharmaceutical, and related industries.

Specifications

| Manufacturer | Hongda |

| Year | 2025 |

| Condition | New |

| Stock Number | 57 |

| Machine Dimensions | 27.6× 39.4 × 51.2 in |

| Machine Weight | 110 lbs |

| Voltage | 110V 60HZ |

| Power | 200 W |

| Speed | 9.8 in/s |

| Material | 304 stainless steel frame |