Single-Lane Powder Packing Machine

Single-Lane Powder Packing Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)3202070

Description

Key Features

- Clean & Low-Noise Operation – Quiet running, ideal for clean environments.

- Fully Automatic – Measures, forms bags, seals, prints dates, and cuts – all in one cycle.

- Smart Control System – PLC + servo + multi-language touch screen for easy, stable operation.

- Real-Time Adjustments – Change parameters without stopping; supports 100 recipe memory.

- Accurate Bag Length Setting – Servo-driven pulling, length set via touchscreen, no parts change.

- Color Mark Tracking – SICK photo sensor ensures precise printing alignment.

- Hygienic & Safe – 304 stainless steel contact parts; Complies with GMP, CE certified, and uses CUL-approved electrical parts.

- Fast & Accurate Filling – Customized auger filler with ±0.5% filling accuracy.

- Tailored Filling System – Filling unit is customized based on material characteristics and test results to ensure precision, avoid clogging, and maintain accuracy.

- Custom Bag Forming Design – Film pulling and forming parts are designed based on bag type, product features, and weight, ensuring optimal bag size and sealing method.

Applications

- This machine is ideal for automatic packaging of free-flowing powder products in the food, pharmaceutical, and chemical industries, such as herbal granules, probiotics, protein powder, meal replacement powder, spirulina powder, instant coffee powder, lotus root starch, tea powder, pearl powder, seasonings, and more.

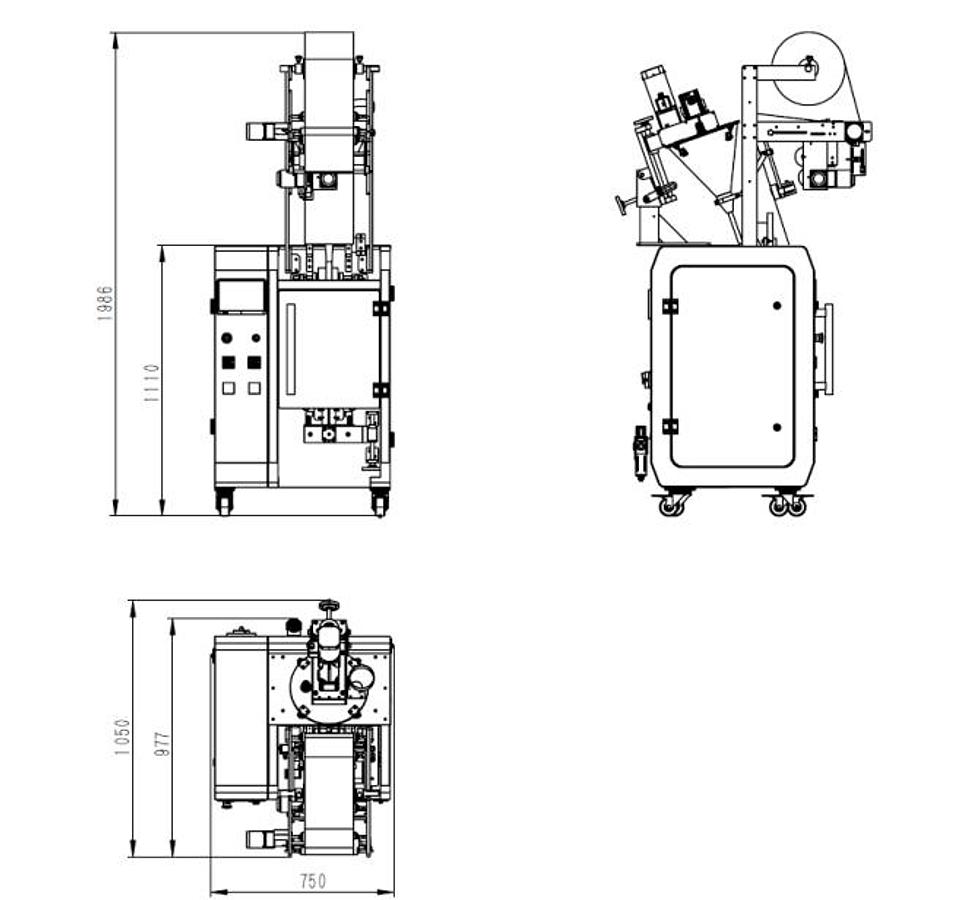

Specifications

| Manufacturer | Hongda |

| Year | 2025 |

| Condition | New |

| Stock Number | 98 |

| Number of Lanes | 1 |

| Dosing Method | Long Auger / Short Auger |

| Film Width | Max. 7.87 inches |

| Bag Forming Speed | 20–80 bags/min |

| Bag Width | 0.8–3.5 inches |

| Bag Length | 2.0–7.1 inches |

| Sealing Type | Back seal |

| Cutting Options | Round / Flat / Zigzag |

| Power Supply | 110Vac, 50/60Hz, 5KW |

| Air Pressure / Consumption | 87–116 psi, 0.6–0.9 CFM |

| Film Thickness | 0.0024–0.0039 inches |

| Film Material | OPP/CPP, OPP/PE, BOPP/VMPET/PE, etc. |