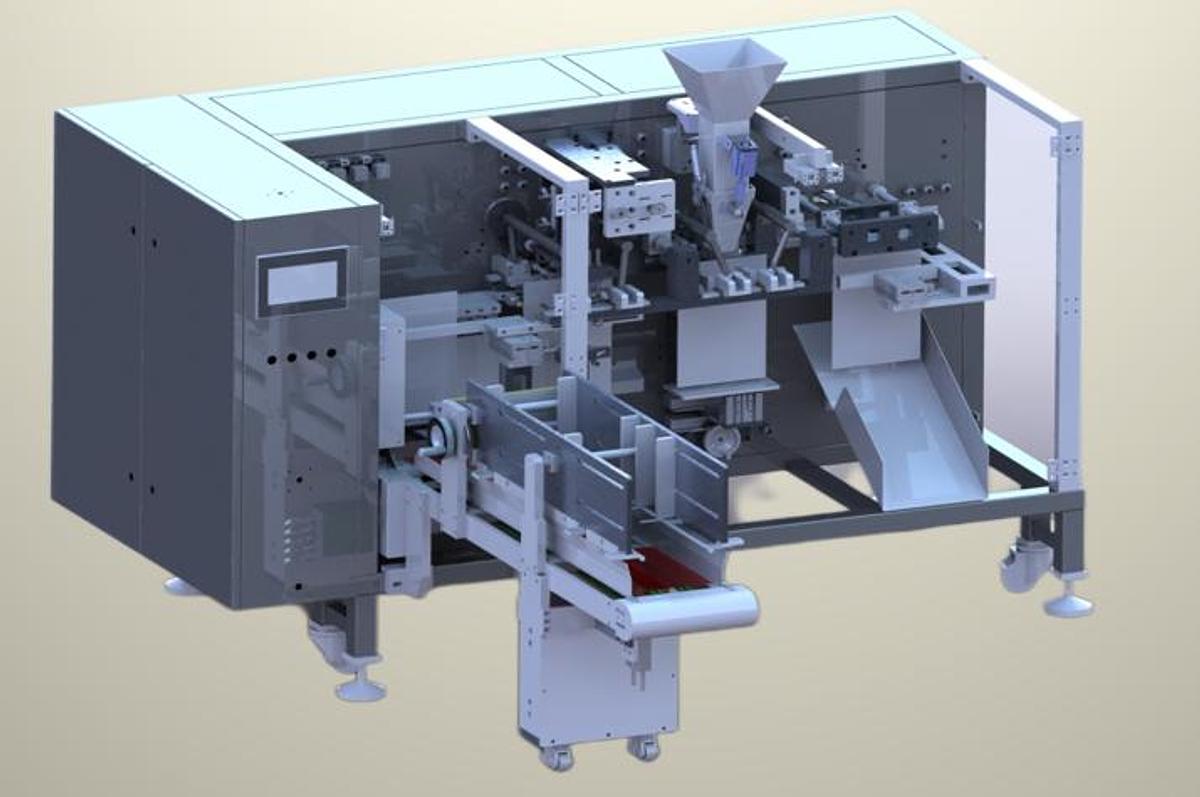

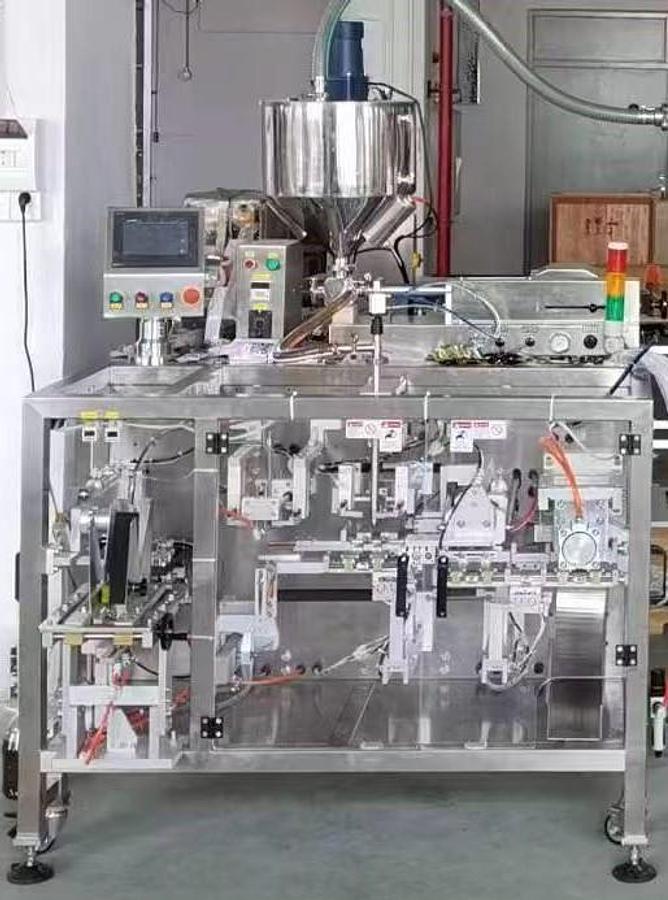

Horizontal Pre-made Pouch Packaging Machine HA-MDPL1

Horizontal Pre-made Pouch Packaging Machine HA-MDPL1

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Description

- This machine is engineered to accommodate a wide variety of premade pouches, offering a sophisticated and highly efficient solution for your packaging requirements. Whether you’re handling powders, granules, liquids, or solids, it delivers consistent, precise performance across diverse applications.

- The system is driven by servo motors to achieve high-speed operation with excellent stability. When air pressure is insufficient, the machine automatically issues an alarm and stops operation to ensure safety.

- Robust construction, user-friendly controls, and seamless integration with weighing and dosing equipment further enhance its versatility and reliability. With this horizontal premade pouch packaging machine, you can achieve streamlined operations and superior packaging quality with every run.

Workflow

- The machine features four dedicated workstations—pouch picking, pouch opening, filling, and sealing—arranged in a single horizontal line. Because each workstation operates independently, all critical actions can occur simultaneously and in parallel. This fully synchronized setup reduces cycle time and significantly increases productivity and throughput, making the machine an ideal choice for high-volume production environments.

- This fully automated packaging machine operates from bag picking to final sealing with high efficiency and precision. The process includes automatic bag picking, bag opening, bag blowing, coding or marking, zipper opening, material filling, and bag tapping for even distribution. Optional functions such as pneumatic vibration and vacuuming or gas flushing are also available. The system continuously monitors the bag-picking and opening steps, issuing alerts if failures exceed preset limits, and provides alarms for overfill time to ensure safe and stable operation. After filling, the bag is automatically sealed, making the entire process suitable for various bag types and packaging needs.

Optional device

- Zipper opening device: For pouches with zippers, this device opens the zipper before the pouch opening process.

- Bag tapping device: This device taps the bottom of the pouch to help relatively light or bulky materials settle smoothly to the pouch’s bottom.

- Coding and printing device: Prints production date, product code, and other information on the pouch surface.

- Pneumatic vibrating hopper device: This device vibrates the hopper to ensure materials flow quickly and prevent clogging. It is a must-have for powder materials.

- Vacuum and gas flushing device: This device removes air from the pouch and fills it with protective gas to keep the contents fresh.

- Full servo configuration: Servo motors are used at all adjustable stations to memorize positions and ensure precise alignment, making pouch changes easier and faster.

- Gusseting Device:Designed specifically for gusseted pouches.

Specifications

| Manufacturer | Hongda |

| Model | HA-MDPL1 |

| Year | 2025 |

| Condition | New |

| Stock Number | 122 |

| Suitable Pouch Types | pillow pouch, stand-up pouch, box pouch, stand-up pouch with zipper, box pouch with zipper |

| Packing Speed | 24–27 bags/min |

| Bag Length | 4.3–11.8 in (110–300 mm) |

| Bag Width | 2.4–7.9 in (60–200 mm) |

| Printable Length | 5.7–11.8 in (145–300 mm) |

| Zipper Opening Width (no hole in the middle) | 3.1–7.9 in (80–200 mm) |

| Zipper Opening Width (with hole in the middle) | 4.7–7.9 in (120–200 mm) |

| Power Supply | 200-230Vac,50/60Hz,4KW |

| Air Consumption | 14 CFM (400L/min) |

| Air Pressure | 87–116 psi (0.6-0.8Mpa) |