Collaborative Palletizing Robot

Collaborative Palletizing Robot

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

1.Overview

- Our Collaborative Palletizing Robot is designed to bring efficiency, flexibility, and ease of use to your end-of-line packaging operations. Engineered for seamless integration into various production environments, this robot excels at automating palletizing tasks with precision and reliability.

2.Key Features

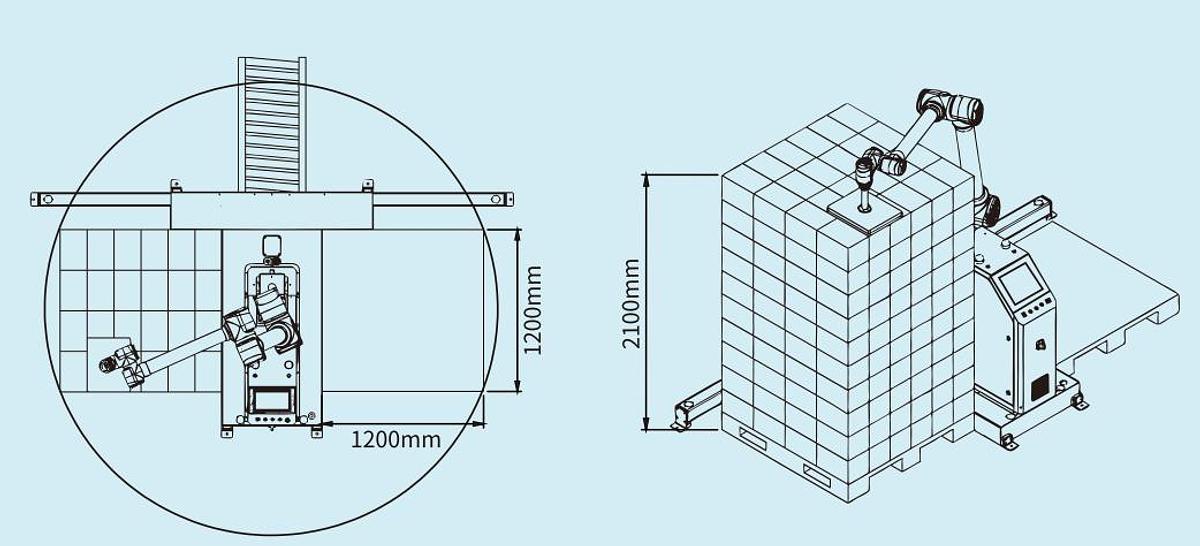

- Portable Mobile Base Frame:The robot features a portable and mobile base frame assembly, greatly improving its convenience and flexibility for a wide range of applications.

- Lightweight & High Suction:Equipped with a lightweight, minimalistic end-of-arm gripper designed for peak performance. Its strong suction power prevents product drops, ensuring secure and reliable handling.

- Mechanical Pallet Positioning System:A simple and practical mechanical system that ensures accurate, consistent pallet placement, making setup and operation easier.

- Intuitive Operating System:Easily control the robot using a high-sensitivity 15-inch capacitive touchscreen. Powered by the advanced Collaborative Palletizing Robot System V1.0, it offers user-friendly controls and powerful functionality.

- Electrical Control Cabinet:The robot features a self-developed, integrated electrical control cabinet that ensures low energy consumption, high-quality components.

3.Advantages

- Easy Programming:Features graphical programming for simple and efficient robot operation. Users can master the programming method in 30 minutes and complete simple tasks within one hour, requiring no prior programming language expertise.

- Safe and Stable:Equipped with industrial-grade force control sensors, the robot ensures high reliability and safety.

- Flexible Deployment:With an integrated, lightweight design and small footprint, the workstation allows quick and easy setup for new tasks, maximizing efficiency.

- Wide Applications:Widely used across industries such as food, pharmaceuticals, electronics (3C), daily chemicals, and printing.

4.Expansion Configuration

- LiDAR Sensor:A non-contact sensor with adjustable detection range. It triggers an alarm and reduces speed when approaching the yellow zone, and immediately stops the system upon entering the red zone.

- Light Curtain Sensor:Stable performance with strong anti-interference capability; high sensitivity and fast response; long service life.

- Safety Fence:Provides physical protection, ensuring safety and reliability. It is included as standard.

Specifications

| Manufacturer | Hongda |

| Year | 2025 |

| Condition | New |

| Stock Number | 123 |

| Robot Payload | 66.1 lbs |

| Working Radius | 74.8in (1900mm) |

| Palletizing Height | Maximum 82.7in (2100mm) |

| Palletizing Speed | <9pcs/min |

| Repeat Positioning Accuracy | ±0.0016in (±0.04mm) |

| Communication Method | TCP/IP |

| IP Rating | IP54 |

| Temperature Range | 0–55 °C (32–131 °F) |

| Power Supply | 200-230Vac,Single-Phase,50Hz,3KW |

| Machine Weight | 771.6 lbs |

| Footprint | 59.3×67.6in (1505×1716mm) |

| Operating Footprint | 124.0×67.6in (3150×1716 mm) |

| Minimum Factory Height | 10.5 ft (3.2 m) |

| Safety Fence | Included |

| Air Consumption | 12.4–15.9 CFM (350–450 L/min) |

| Air Pressure | 72–102 psi (0.5–0.7 MPa) |