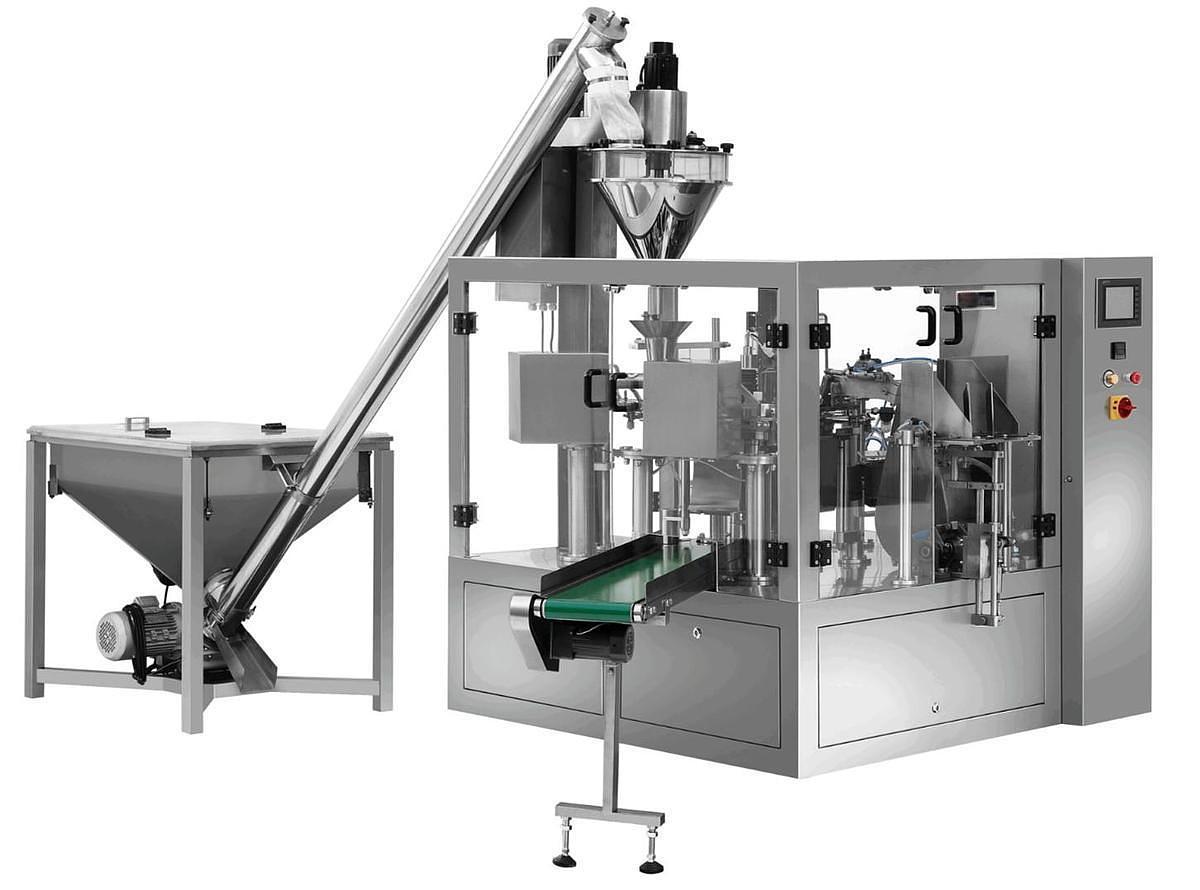

Rotary Pre-made Pouch packaging machine with Powder Filling Feeder

Rotary Pre-made Pouch packaging machine with Powder Filling Feeder

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Powder Filling Feeder

1.Overview

- The screw-type powder filling machine is a specialized packaging equipment designed to accurately measure and fill powdered products into containers such as bottles, bags, or cans.

- It utilizes a rotating screw mechanism for precise dosing and is suitable for industries such as food, pharmaceuticals, chemicals, and cosmetics.

2.Core Features

- Screw Filling System

- Uses a screw feeder (screw auger) for measurement and filling.

- Adjustable screw speed and pitch enable both volumetric and weight-based accurate filling.

- High Precision Filling

- Suitable for powders with either good or poor flowability.

- Some models are equipped with weighing sensors, with an accuracy range of ±0.5% to ±1%.

- Wide Applicability

- Can handle a variety of powders, such as spices, flour, milk powder, protein powder, and pharmaceuticals.

- The hopper and screw size are adjustable, allowing compatibility with different container types.

- Waste Reduction

- Anti-drip design prevents powder spillage.

- Some models include vibration or agitation devices to prevent powder caking.

- Automation Options

- Semi-automatic (manual feeding) or fully automatic (integrated with a production line, including conveyors and sealers).

- PLC control with a touch-screen interface for easy operation.

- Compliance & Safety

- Made of food-grade stainless steel (SS304/SS316), meeting GMP, FDA, or CE standards.

3.Applications

- Food Industry: Milk powder, coffee powder, seasonings, flour, sugar, etc.

- Pharmaceutical Industry: Pharmaceutical powders, health supplements, active pharmaceutical ingredients (APIs).

- Chemical Industry: Laundry powder, pigments, additives.

- Cosmetic Industry: Talcum powder, loose powder, powdered cosmetics.

Rotary Pre-made Pouch packaging machine

1.Introduction

- This Machine is a versatile, high-performance premade pouch packing machine designed for a wide range of pouch formats. Suitable for both small and large packaging applications, it serves industries such as food, pet care, pharmaceuticals, and household products.

- Built with advanced technology and precision components, it ensures safe, efficient, and stable operation. The system uses a rotary indexing structure with multiple working stations to complete automatic bag pickup, opening, filling, sealing, and discharge.

- With intuitive controls, fast changeovers, and flexible filler integration, it is engineered for accuracy, speed, and ease of use, helping manufacturers boost productivity and reduce labor.

- Wide Bag Compatibility: Suitable for a broad range of packaging formats,including flat bags, stand-up pouches, zipper bags, and stand-up zipper bags.

2.Key Advantages

- Supports a wide variety of premade pouch styles.Operators can easily switch between bag formats by manually adjusting the grippers—no complex tools or programming required. This simple yet effective mechanism allows for fast adaptation to different packaging needs, boosting line flexibility and minimizing downtime.

- Smart Control System: PLC + HMI interface for precise, user-friendly operation,giving operators full control over every step of the packaging process with minimal training required.

- Efficient Bag Handling: Up-to-down pouch magazine ensures smooth loading and less downtime.

- Enhanced Safety: Includes safety door, fault alarms, and No Bag – No Fill – No Seal system.

- Easy Maintenance: Wash-down structure and automatic air exhaust for quick cleaning.

- Stable Performance: Grooved cam system ensures accurate, synchronized bag movement.

3.How It Works

- It utilizes an automated rotary indexing system with 8 working stations to complete the full packaging cycle—bag loading, opening, filling, sealing, and discharging. Each station performs a specific task, and the rotary motion ensures smooth, continuous operation with minimal human intervention. The system integrates:

- Vacuum bag pick-up from a pouch magazine.

- Bag opening via air inflation and mechanical grip.

- Precision filling using optional fillers (volumetric, auger, or multi-head).

- Heat sealing for a strong and clean finish.

- Reject station for faulty pouches.

Specifications

| Manufacturer | Hongda |

| Model | HDA-300RPP&PFF |

| Year | 2025 |

| Condition | New |

| Stock Number | 125 |

| Filling Machine | Screw-Type Powder Filling Machine |

| Hopper Capacity | 6.6USG/13USG |

| Weighing Range | 0.35–1.76 oz/1.76–3.53 oz/3.53–17.64 oz |

| Dosing Accuracy | ±0.035-0.176 oz |

| Applicable Bag Type | Flat bag,stand up bag,zipper bag,stand-up zipper bag |

| Bag Width Range | 7.1 – 11.8inches(180-300mm) |

| Bag Length Range | 5.9 – 17.7inches(150-450mm) |

| Filling Weight | ≤ 5.5 lb |

| Packaging Speed | ≤50 bags/min |

| Power Supply | 200-240Vac,3-Phase,50/60Hz,6.5KW |

| Air Pressure | 87-101PSI(0.6-0.7MPa) |

| Compress Air | ≥14.1 CFM(≥0.4 m³/min) |

| External Dimensions | 81.9" × 67.7" × 65.0" |