Rotary Pre-made Pouch Packaging Machine with Multiheads Standard Combination Scales

Rotary Pre-made Pouch Packaging Machine with Multiheads Standard Combination Scales

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Multiheads Standard Combination Scales

Application Range:

- Suitable for the quantitative weighing of various granular, flake, spherical, or irregularly shaped materials, such as grains, pasta, candy, sunflower seeds, potato chips, coffee beans, nuts, puffed foods, biscuits, chocolate, pet food, and frozen foods.

- It is also suitable for weighing non-food materials, such as screws, bolts, small hardware, and plastic parts.

Features:

- Modular control system for easy troubleshooting and cost-effective maintenance

- Multi-language control system

- IP65 waterproof and dustproof design

- Amplitude of linear vibrating feeder can be adjusted automatically or manually based on material characteristics

- Weight sensors and photoelectric sensors detect material feeding quantity

- Preset sequential discharge function to prevent material blockage

- Production data can be accessed or downloaded to a PC

- Material contact parts are easily detachable for cleaning without the need for tools

- Remote control and Ethernet connection are available as optional features

Rotary Pre-made Pouch packaging machine

Introduction

- This Machine is a versatile, high-performance premade pouch packing machine designed for a wide range of pouch formats. Suitable for both small and large packaging applications, it serves industries such as food, pet care, pharmaceuticals, and household products.

- Built with advanced technology and precision components, it ensures safe, efficient, and stable operation. The system uses a rotary indexing structure with multiple working stations to complete automatic bag pickup, opening, filling, sealing, and discharge.

- With intuitive controls, fast changeovers, and flexible filler integration, it is engineered for accuracy, speed, and ease of use, helping manufacturers boost productivity and reduce labor.

- Wide Bag Compatibility: Suitable for a broad range of packaging formats,including flat bags, stand-up pouches, zipper bags, and stand-up zipper bags.

Key Advantages

- Supports a wide variety of premade pouch styles.Operators can easily switch between bag formats by manually adjusting the grippers—no complex tools or programming required. This simple yet effective mechanism allows for fast adaptation to different packaging needs, boosting line flexibility and minimizing downtime.

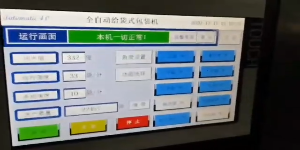

- Smart Control System: PLC + HMI interface for precise, user-friendly operation,giving operators full control over every step of the packaging process with minimal training required.

- Efficient Bag Handling: Up-to-down pouch magazine ensures smooth loading and less downtime.

- Enhanced Safety: Includes safety door, fault alarms, and No Bag – No Fill – No Seal system.

- Easy Maintenance: Wash-down structure and automatic air exhaust for quick cleaning.

- Stable Performance: Grooved cam system ensures accurate, synchronized bag movement.

How It Works

- It utilizes an automated rotary indexing system with 8 working stations to complete the full packaging cycle—bag loading, opening, filling, sealing, and discharging. Each station performs a specific task, and the rotary motion ensures smooth, continuous operation with minimal human intervention. The system integrates:

- Vacuum bag pick-up from a pouch magazine.

- Bag opening via air inflation and mechanical grip.

- Precision filling using optional fillers (volumetric, auger, or multi-head).

- Heat sealing for a strong and clean finish.

- Reject station for faulty pouches.

Specifications

| Manufacturer | Hongda |

| Model | HDA-300RPP&CSMH1.6L |

| Year | 2025 |

| Condition | New |

| Stock Number | 127 |

| Single Weighing Range | 0.4-53 oz |

| Weighing Accuracy | X (0.5) class, ±0.01-0.05 oz, (For reference) |

| Maximum Weighing Speed(with 10 heads ) | 70 times/min |

| Maximum Weighing Speed(with 14 heads ) | 120 times/min |

| Hopper Capacity | 54.1 fl oz |

| Operating Interface | 7-inch touch screen |

| Drive Method | Stepper motor |

| Material contact surfaces | 304 stainless steel with a patterned plate |

| Vibratory Main Feeder | 1.6L single-door hopper |

| Applicable bag type | Flat bag,stand up bag,zipper bag,stand-up zipper bag |

| Bag Width Range | 7.1–11.8inches(180-300mm) |

| Bag Length Range | 5.9–17.7inches(150-450mm) |

| Filling Weight | ≤5.5 lb |

| Packaging speed | ≤50 bags/min |

| Power Supply | 200-240Vac,3-Phase,50/60Hz,6.5KW |

| Air Pressure | 87-101PSI(0.6-0.7MPa) |

| Compress Air | ≥14.1 CFM(≥0.4 m³/min) |