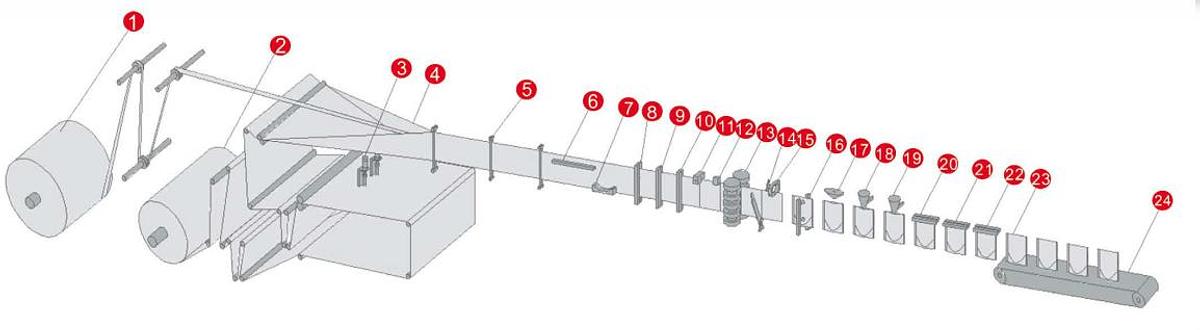

Horizontal Stand-up Pouch with Zipper Roll Film Packaging Machine

Horizontal Stand-up Pouch with Zipper Roll Film Packaging Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Key Features:

- The film unwinder comes with two sets of film rolls and an integrated film storage system, allowing for continuous film splicing without stopping the machine. When one roll runs out and switches to the next, the system detects the splice tape location and automatically removes the waste film at the joint. During the filling process, the machine suspends filling over the waste film area, which greatly improves operational efficiency and reduces film and product waste. This function is also ideal for handling splice joints on printed film rolls in printing facilities.

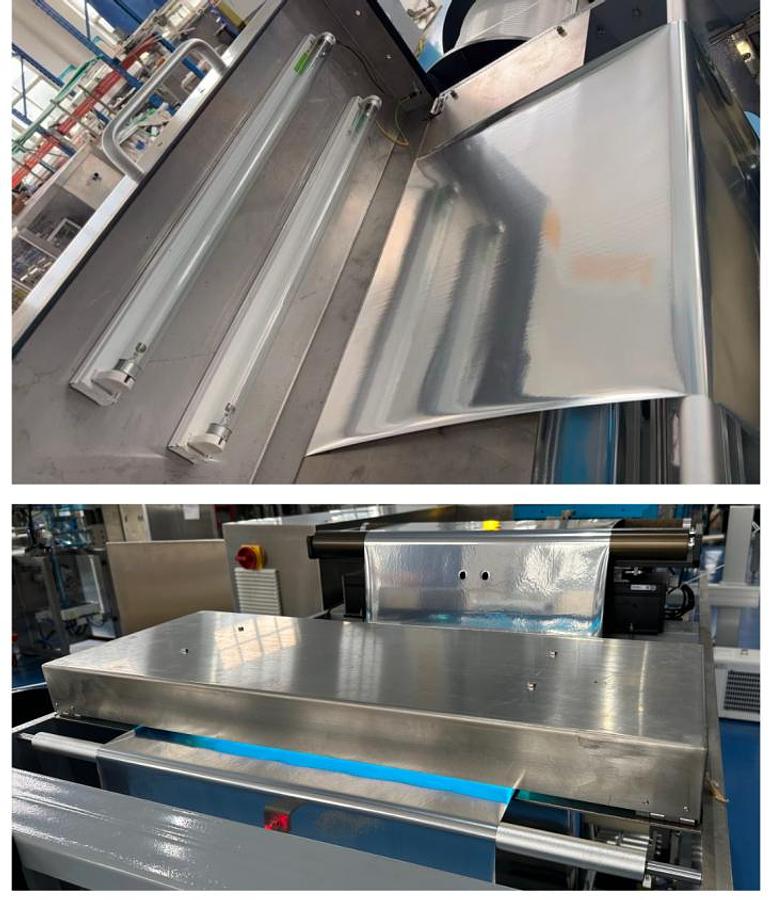

- UV sterilization is applied before the film forming process.

- The photoelectric edge guide effectively keeps roll materials aligned, solving issues caused by sideways drifting on fast production lines.

- The bottom and vertical sealing units feature screw rod adjustments for easy, lightweight operation and quick fine-tuning.

- Utilizes chilled liquid circulation to cool and smooth the heat-sealed film, improving surface quality. The system offers adjustable settings horizontally and vertically to accommodate different pouch shapes.

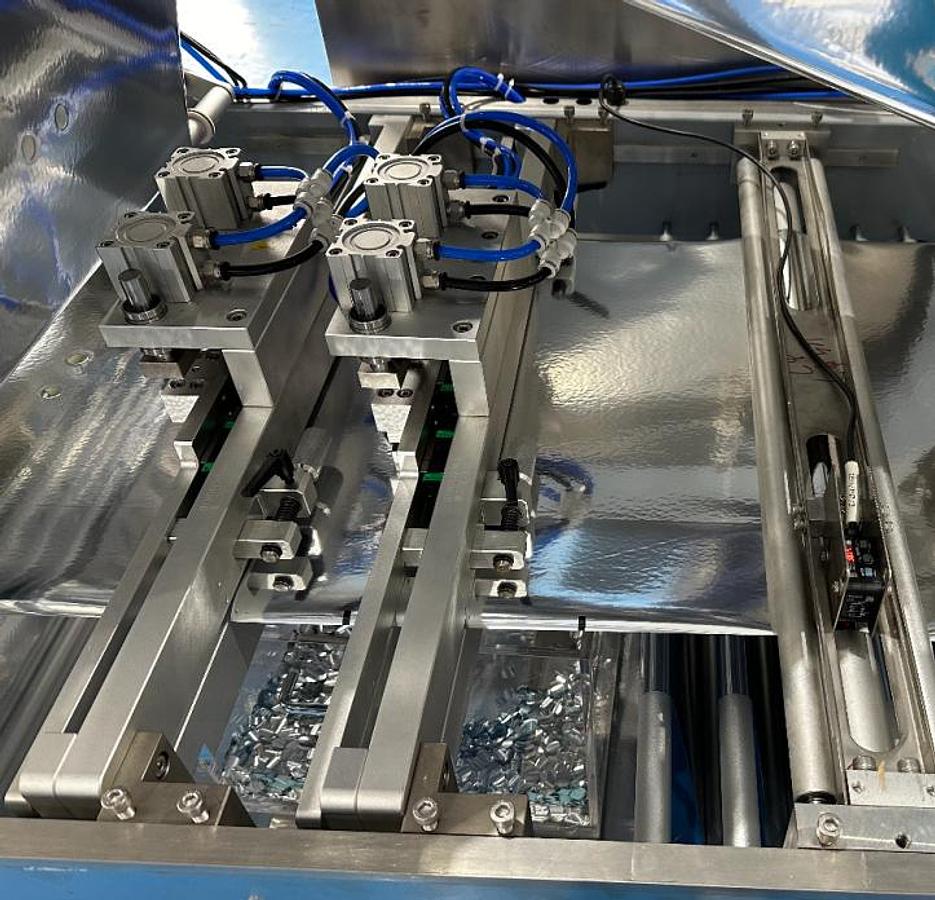

- Uses vacuum pumps with mechanical suction cups for easy, reliable bag opening. Low wear and tear, pollution-free and ensures a high bag opening success rate.

Specifications

| Manufacturer | Hongda |

| Year | 2025 |

| Condition | New |

| Stock Number | 155 |

| Minimum Pouch Size (W × H) | 4.3''×5.5'' (110×140 mm) |

| Maximum Pouch Size (W × H) | 7.9''×12.8'' (200×325 mm) |

| Max Packing Volume | 33.8 fl oz (1000ml) |

| Packing speed | 70–80 packs/min (depending on the actual material) |

| Film Thickness | 3.2–5.5 mil |

| Machine Size (L × W × H) | 433.1″ × 55.9″ × 82.7″ |

| Operating Temperature | 14℉ to 131℉ |

| Power Supply | 200-240Vac, 50/60Hz, 23KW |

| Air Pressure | 87.0–101.5 psi (0.6–0.7 MPa) |

| Air Consumption | 14.1 CFM (400 L/min) |