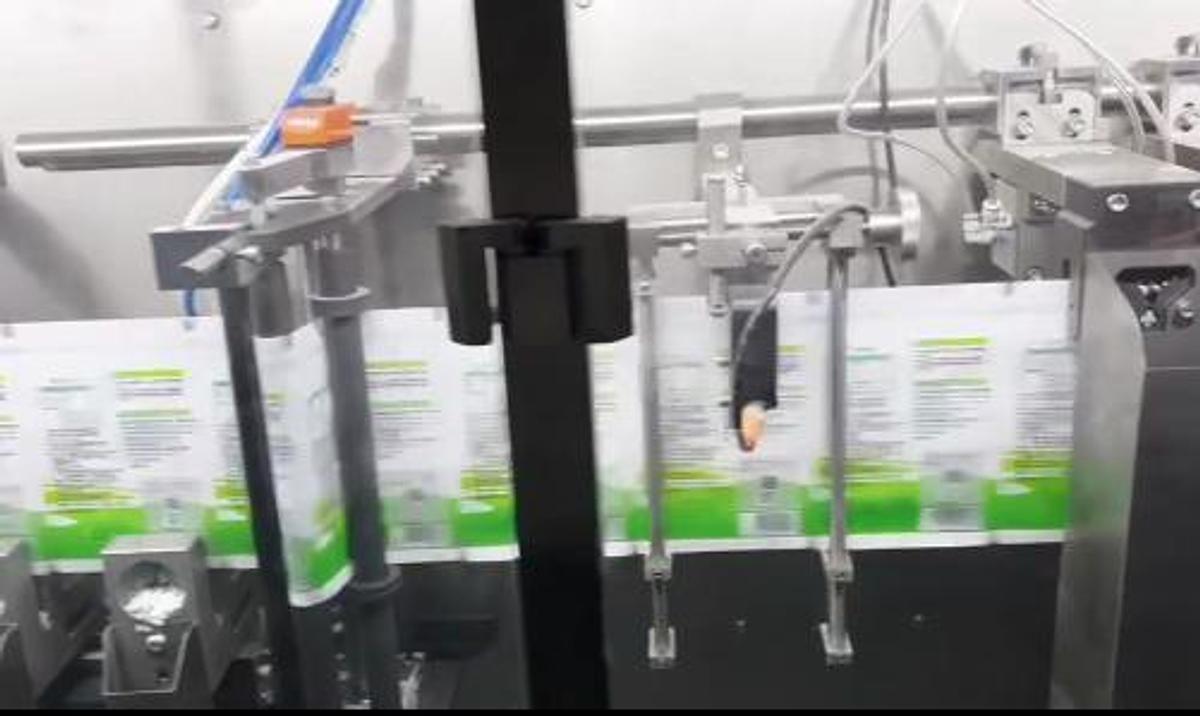

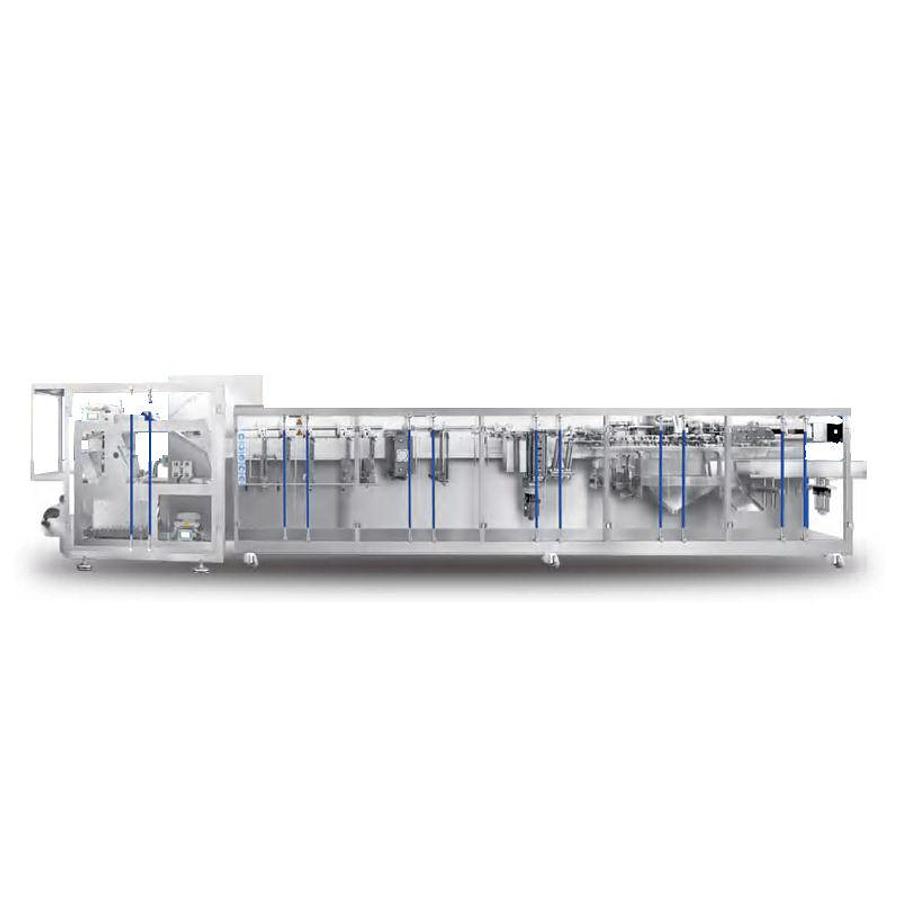

Dual-Lane Form-Fill-Seal Machine for Zipper Doypack Pouches

Dual-Lane Form-Fill-Seal Machine for Zipper Doypack Pouches

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Advantages

- Siemens PLC and HMI control ,convenient to operating,easy and simple maintain.

- Advanced photoelectric sensor tracking system for detecting tap connections, film tension/pulling, bag opening, film shortfalls, and other functions.

- Automatic film alignment system that performs double alignment before doypack bag forming.

- Flexible size adjustment: digital control handles for sealing stations

- Film release speed regulator ensures smooth and stable unwinding for both large and small film rolls

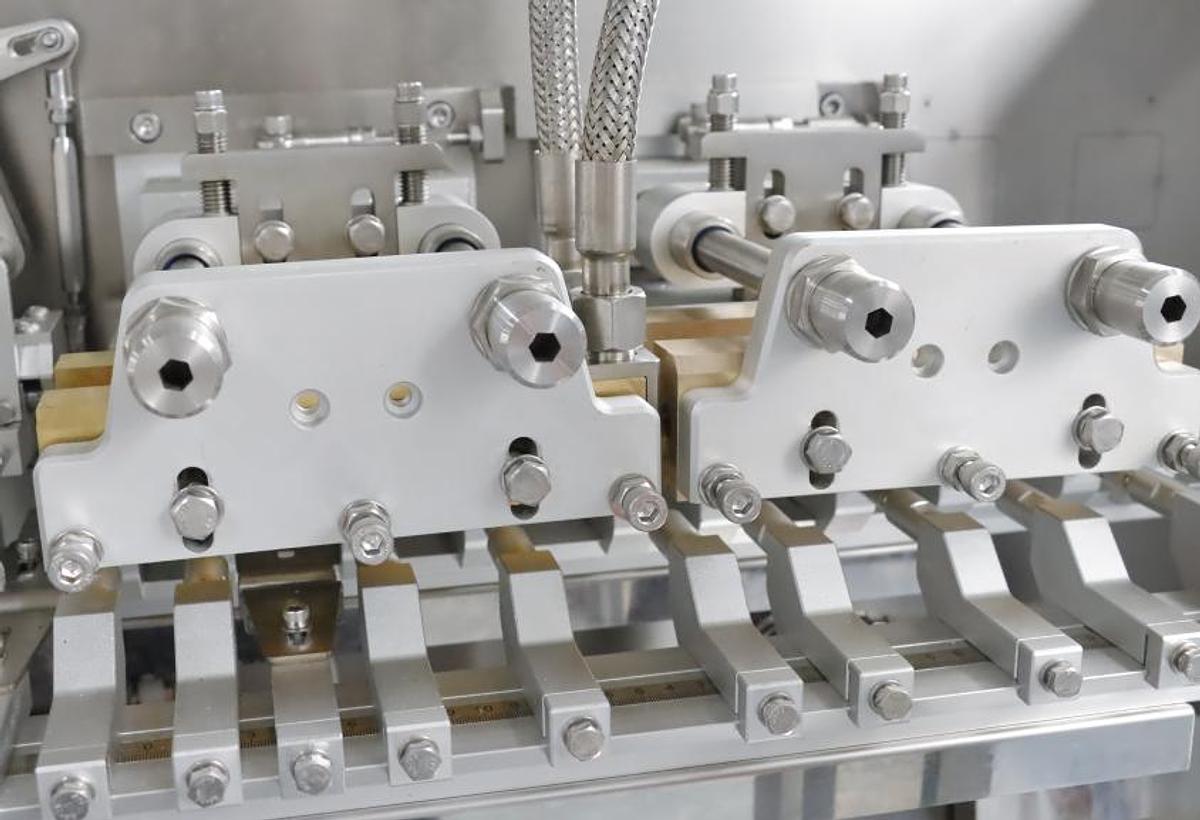

- Multiple sealing steps are required to ensure sealing quality. Zipper sealing is an additional process.

Features

- The independent film frame device provides stable doypack pouch forming through precise film release and speed control, while the 360-degree dust cover keeps the film clean, making it perfect for food packaging.

- Sensor detects eyemark to trigger precise hole punching and controls pouch pulling for accurate positioning.

- A film alignment device positioned before the bottom hole punching station ensures precise and consistent alignment for accurate hole placement.

- Advanced bottom doypack forming design with easily adjustable bottom depth for precise pouch shaping.

- All pouch sealing stations feature adjustable handles for easy size changes.

- No bag detected, no filling.

- Hot and cold sealing ensure smooth, reliable seals.

Specifications

| Manufacturer | Hongda |

| Year | 2025 |

| Condition | New |

| Stock Number | 156 |

| Minimum Size (W × L) | 2.4"×5.1" (60×130 mm) |

| Maximum Size (W × L) | 8.4"×13.8" (215×350 mm) |

| Maximum Packing Volume | 33.8 fl oz (1000 ml) |

| Filler | 20 heads multihead weighter with two fillers |

| Speed | 60-80 bags/min |

| Film Thickness | 60–180 μm |

| Film Roll Outer Diameter | 19.7" (500 mm) |

| Film Roll Inner Diameter | 2.8"–3.1" (70–80 mm) |

| Power Supply | 200-240Vac,50/60Hz,12 Kw |

| Compressed Air | 21.2 CFM (600 L/min) |