Automatic Corner Labeling Machine 210

Automatic Corner Labeling Machine 210

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

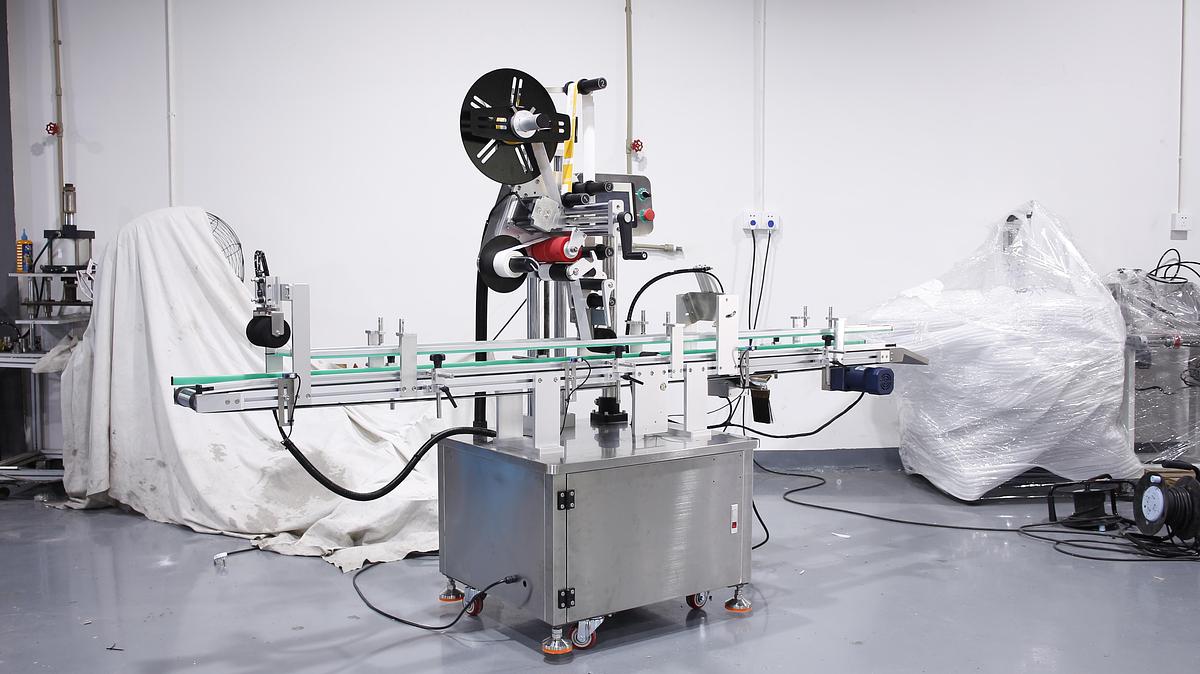

Working Principle

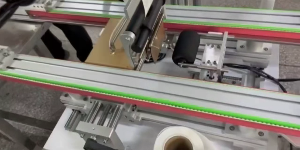

- Products are loaded onto the conveyor and transported to the labeling section.

- A sensor detects each product and triggers the control system to apply the label at the correct position.

- Label position can be adjusted for front and rear placement.

- Operation process: Place product → Conveyor transports product → Product detection → Label application → Label covering → Label folding mechanism folds the label → Conveying and discharging.

Product Features

- PLC control with stepper motor drive and touchscreen interface, easy operation.

- Simple and quick parameter setting; labeling speed and count are clearly displayed.

- When the leading edge of the label partially sticks to the product, it is immediately carried away by the product.

- Product detection via sensor; PLC processes the signal, and front/rear label position can be adjusted via settings.

Specifications

| Year | 2025 |

| Condition | New |

| Stock Number | 196 |

| Applicable Product Length | 1.97–7.87 in (50–200 mm) |

| Applicable Product Width | 1.97–7.87 in (50–200 mm) |

| Applicable Product Height | 1.97–7.87 in (50–200 mm) |

| Applicable Label Length | 1.18–11.02 in (30–280 mm) |

| Applicable Label Width | 1.18–5.12 in (30–130 mm) |

| Labeling Speed | 15–20 pcs/min (depends on product size and label material) |

| Labeling Accuracy | ±0.08 in (±2 mm) |

| Conveyor Dimensions | 94.49×7.87×27.56 in (2400×200×700 mm) |

| Conveyor Height | 27.56 in (700 mm) |

| Belt Conveyor Speed | 0–1102 in/min (adjustable) (0–28 m/min) |

| Power Supply | 200-240Vac,50/60HZ,0.5KW |

| Dimensions (L×W×H) | 94.88 × 27.56 × 59.06 in (2410 × 700 × 1500 mm) |

| Equipment Weight | 441 lb (200 kg, actual weight may vary) |