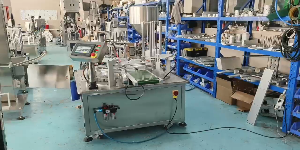

Automatic Rotary Dual-Cup Filling and Sealing Machine

Automatic Rotary Dual-Cup Filling and Sealing Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Application

- Suitable for a wide range of materials, including drinking water, yogurt, milk, soy milk, soybean paste,porridge, honey (spoonable), jelly, rice wine, fruit juice beverages, jam, condiments, hot pot seasonings, and other similar products.

Features

- Fully automatic operation including cup placement, filling, film placement, sealing, and cup discharge.

- The quantitative feeder operates on a piston principle, ensuring precise filling.

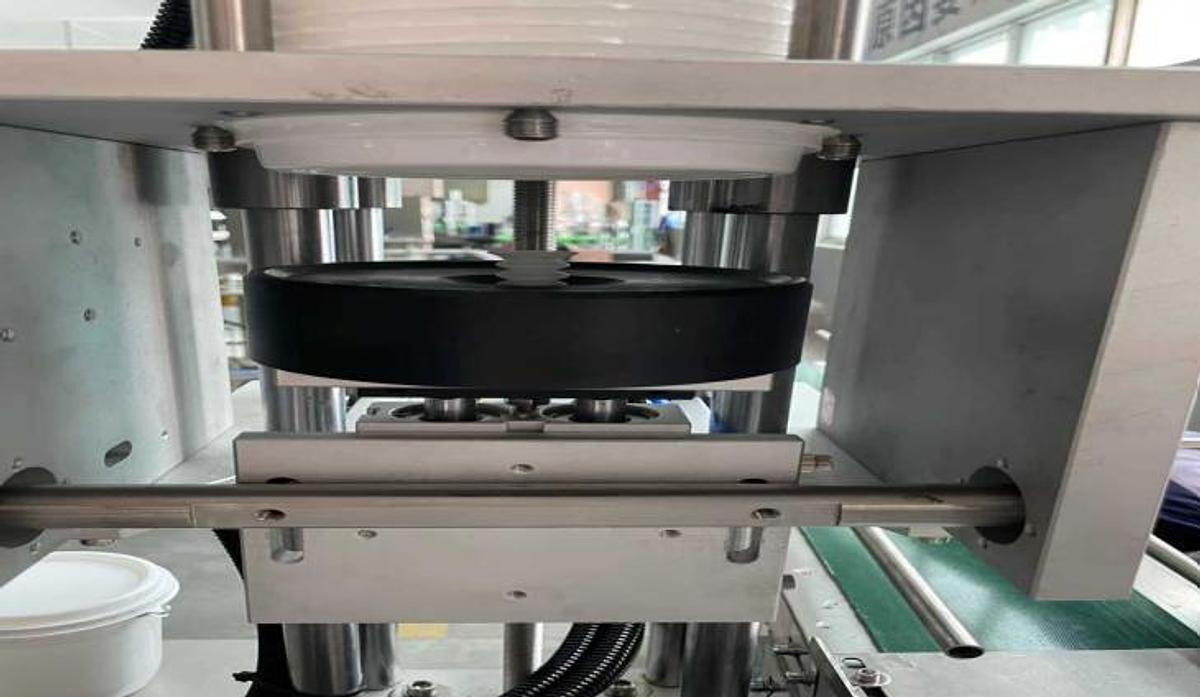

- Molds on the rotary worktable are simple and easy to replace.

- Temperature control range: 32–572°F, with precise constant temperature settings, even heating, smooth sealing, stable equipment performance, simple workflow, and easy operation. Suitable for various sealing materials.

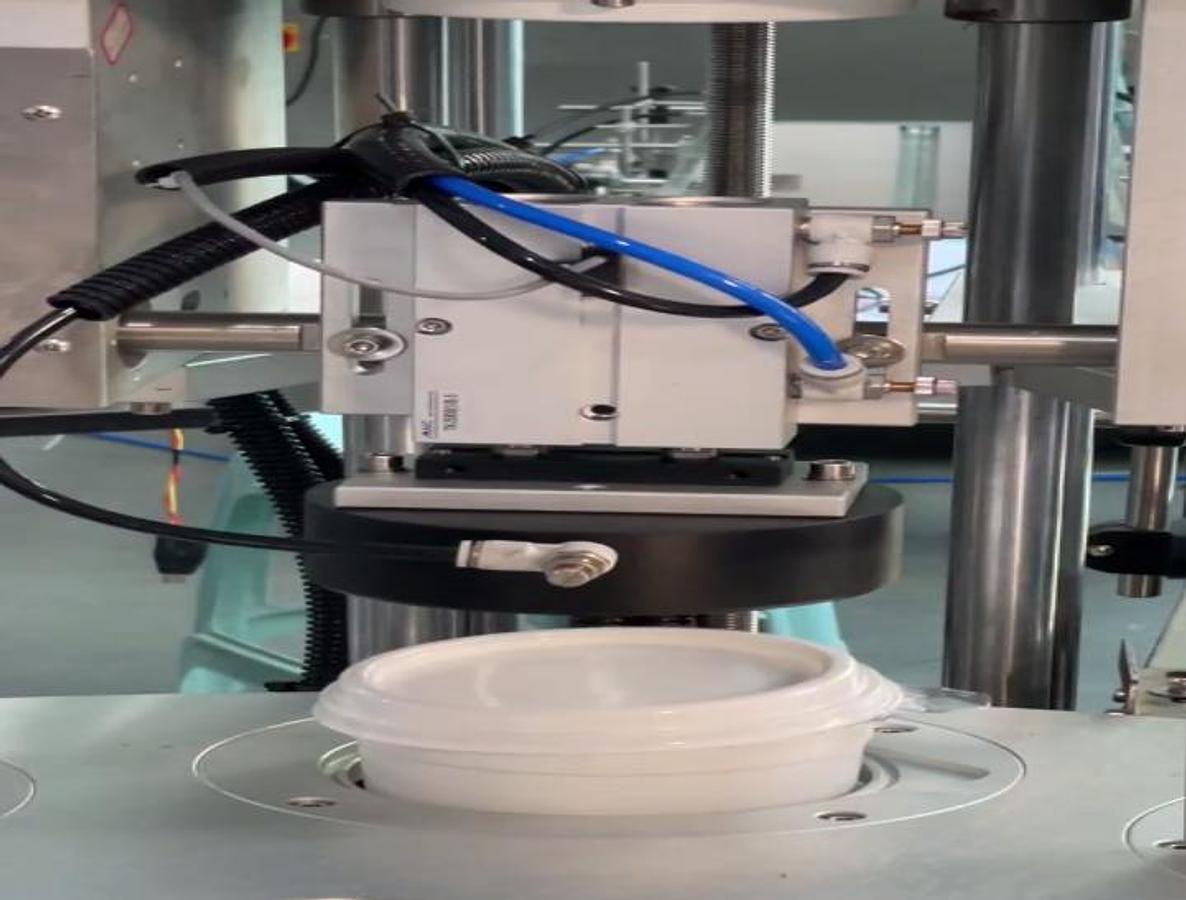

- Automatic Lid Placement and Sealing: The lids are manually stacked and placed onto the track. After the cups are sealed with aluminum foil, they move to the lid station for automatic lid placement and pressing.

Specifications

| Year | 2025 |

| Condition | New |

| Stock Number | 200 |

| Production Capacity | 900–2,000 cups/hour |

| Hopper Capacity | 13.2 gallons (50L) |

| Filling Range (one range per machine, chosen by cup size) | 0.34–1.69 fl oz;1.01–8.45 fl oz;1.69–16.91 fl oz |

| Cup Height | 1.18–5.51 in (30–140 mm) |

| Cup Diameter | 0.98–4.53 in (25–115 mm) |

| Dimensions | 63.0 × 55.1 × 72.8 in |

| Power Supply | 200-240Vac,2-Phase,50/60Hz,1.5KW |