Four-Channel Counting and Filling Machine HA-4S-A

Four-Channel Counting and Filling Machine HA-4S-A

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Introduction

- Uses high-speed photoelectric sensors to detect falling objects, combined with a highly optimized algorithm to calculate and count quantities. Accurate counting and filling are achieved through synchronized control modules.

- Features a compact and elegant design with easy maintenance.

- Widely applicable in the pharmaceutical, health supplement, and food industries for counting, filling, and mixed packaging of various solid products, such as tablets, coated tablets, soft and hard capsules, seeds, nuts, frozen pellets, etc.

- Can be used as a standalone machine or integrated with other equipment from our company to form a complete packaging production line.

Working Principle

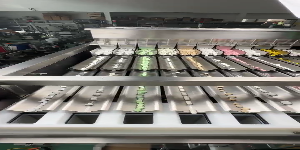

- Different tablets are loaded into the top hoppers and fed via vibratory feeders, forming continuous lines that slide to the discharge ports.

- Each tablet drops individually through a detection channel, where a photoelectric sensor with infrared scanning sends signals to a high-speed microprocessor (MCU).

- The system counts the tablets and dispenses the set quantity into containers.

Product Features

- Wide applicability: The same machine can count and fill different products; switching between different specifications is simple and easy.

- High counting accuracy: Uses an independent optical detection system to ensure precise counting and high speed.

- Multi-stage vibratory feeding: Each stage can be adjusted independently, providing faster material flow with uniform orientation.

- Hygienic design: Surfaces made of stainless steel and food-grade, non-toxic, chemically stable non-metallic materials; easy to clean with no dead corners.

- User-friendly operation: Intelligent design allows all operating parameters to be set directly via the HMI.

- Modular mechanical adjustments: Structured and embedded snap-fit design makes product changeover and cleaning simple and time-saving.

- Automatic fault diagnosis: Real-time monitoring, alarm, and display of operational status.

- Parameter storage: Previously used parameters can be recalled, eliminating the need for re-adjustment when changing products.

- Flexible production: Can be used as a standalone machine or integrated into a production line.

- Configurable feeding lanes: Multiple combinations of feeding tracks available to meet different counting and filling requirements.

Specifications

| Manufacturer | Hongda |

| Model | HA-4S-A |

| Year | 2025 |

| Condition | New |

| Stock Number | 201 |

| Vibrating table channels | 1×4 lanes |

| Production capacity | 30–40 bags/min |

| Counting range | 1–9,999 pieces |

| Material specifications | Diameter 10–40 mm; Length 10–40 mm |

| Air supply | 72–102 psi (0.5–0.7 MPa) |

| Air consumption | 4.6 SCFM (130 L/min) |

| Power supply | Single-phase 220 V, 50/60 Hz, 1 kW |

| Weight | 551 lb |