2-lane Granule Packaging Machine

2-lane Granule Packaging Machine

Contact us for price

Location:Ontario, CA

or

Call +1(626)320-2070

Description

Hongda provides complete processing and packaging equipment and solutions, with robotic integration for fully automated production lines. Learn more at www.hongdaamerica.com.

Machine Overview

- Fully automatic: measures, forms bags, seals, codes, and cuts.

- PLC control with multilingual touchscreen – intuitive, stable, and easy to operate.

- Adjustable parameters during operation,with production speed & batch display, fault self-diagnosis, and storage for 100 product sets. Ethernet port for EMS integration.

- Servo-driven heat sealing and bag pulling – bag length adjustable via touchscreen, accurate and hassle-free.

- Sick photoelectric tracking ensures precise logo alignment on printed films.

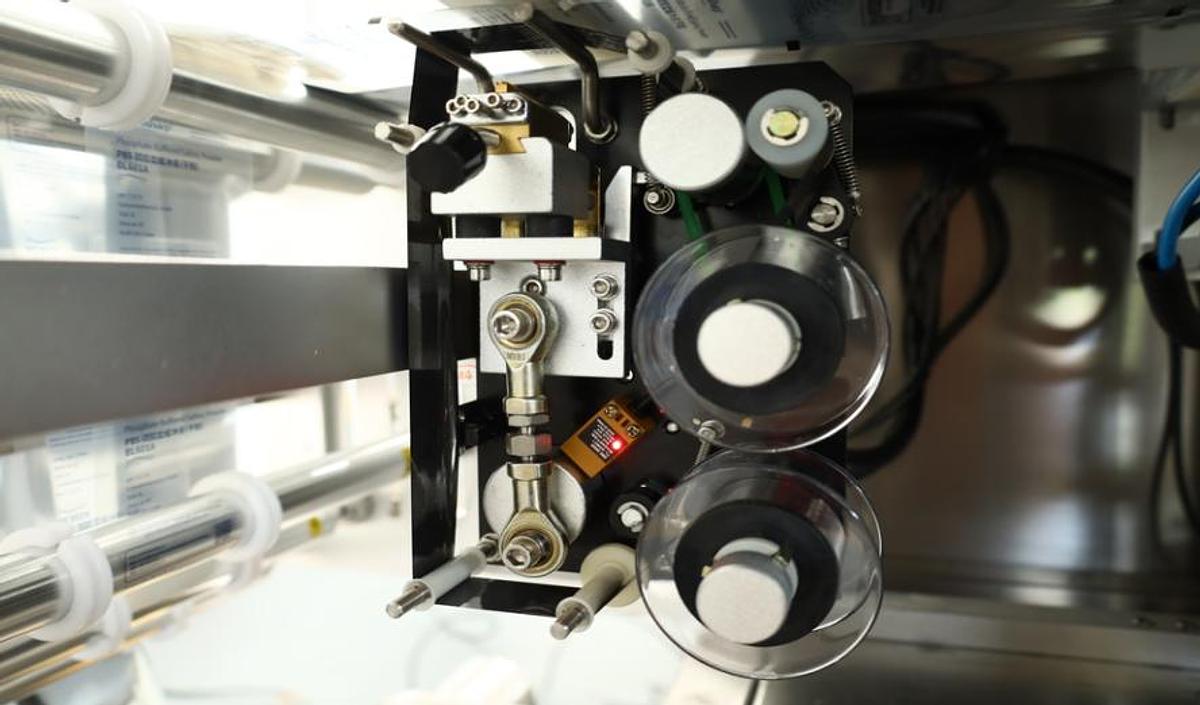

- Swing cup filling system – fast, precise (±0.5%) filling.

- All parts in contact with materials are made of high-quality 304 stainless steel, ensuring contamination-free operation and easy cleaning.

Applicable Industries

- Ideal for granular materials in food, pharma, and chemicals – sugar, coffee, herbs, spices, millet, and more.

- Protects against oxidation, mold, spoilage, and moisture, keeping products fresh and extending shelf life.

Working Process:

- Operators load the film onto the unwinding shaft.

- Manual or automatic vacuum feeding supplies the material (linear sensor detects material level: feeding stops when full, resumes when low).

- Screw-type filling and dosing.

- Longitudinal sealing (with easy-tear or round-corner options) and transverse sealing (easy-tear).

- The machine automatically completes feeding, measuring, discharging, date printing, bag forming, sealing, and cutting.

Specifications

| Year | 2025 |

| Condition | New |

| Stock Number | 244 |

| Measuring method | Swing cup |

| Bag forming speed | 20–80 cuts/min |

| Maximum film roll width | 11.8 in (300mm) |

| Bag width | 0.59–1.97 in (15-50mm) |

| Bag length | 1.58–7.09 in (40-180mm) |

| Sealing type | Back seal |

| Cutting type | round corner / straight / serrated |

| Power supply | 200-240Vac,50/60Hz,11 Kw |

| Air consumption | 87–116 psi |

| Film thickness | 2.4–3.9 mil |

| Film material | OPP/CPP, OPP/PE, BOPP/VMPET/PE, etc. |